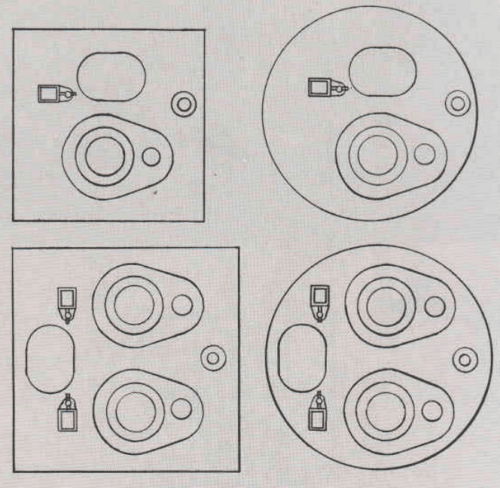

Allied Ejecto Sewage Ejector

Features

- Economical

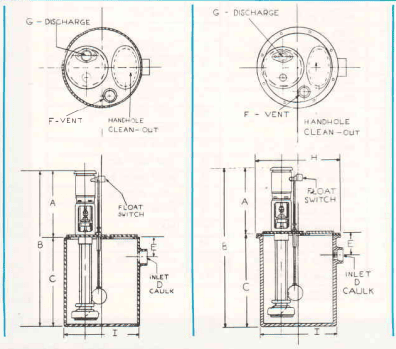

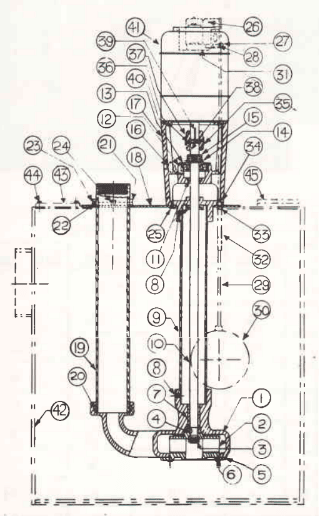

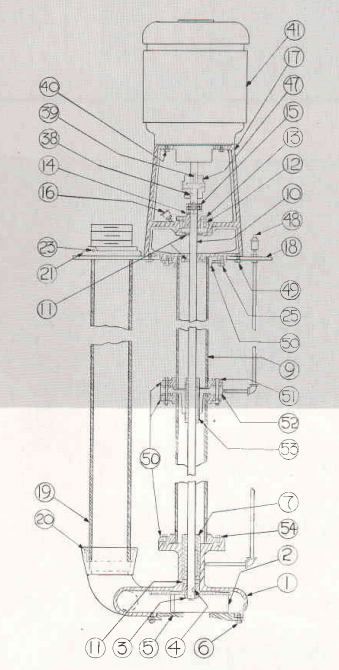

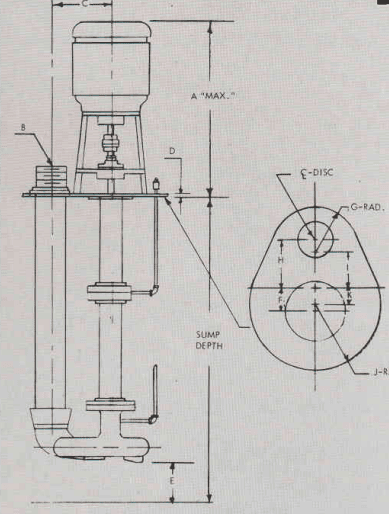

- Factory Assembled Package

- Full 3″ Screenless Non-Clog

- Passes Through 30″ Doorway

- 3 Water Closet Capability

- Low Cost Trouble-Free Operation

- For That Extra Playroom or Basement Bathroom

- Will Pump All Matter Which Passes Through:

Garbage Disposal, Sink, Laundry Tray, Water Closet, Waste Line

| Capacity GPM | Head in Feet | Horse Power |

|---|---|---|

| 25 | 25 | 3/4 |

| 75 | 20 | |

| 115 | 15 | |

| 140 | 10 |

The Allied “Ejecto” is an efficient, economical packaged sewage pump designed primarily for “that extra set of fixtures” which are located such that gravity drainage is not possible nor practical. The entire unit will pass through a 30″ doorway