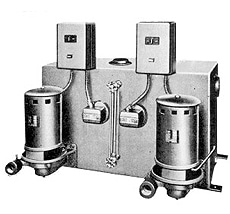

Allied Type VC

Features

- Completely Assembled

- Control Mounted and Interwired

- Leakless Operation

- Economical

- Stainless Steel Shafts

- Welded Steel or Galvanized Steel receivers

The Allied “VC” is an efficient, engineered packaged condensation return unit designed for long trouble free operation in gravity heating systems for industrial institutional and residential applications. It is completely assembled to make for an economical package in either single or duplex arrangements.

Allied Type VC Dimensions